Introduction

Anaerobic digestion (AD) is a time-tested yet increasingly innovative technology that converts organic waste into renewable energy and nutrient-rich byproducts. From its humble beginnings to becoming a centerpiece of India’s clean energy mission, AD has undergone a remarkable transformation. This blog explores the journey of anaerobic digestion technology, tracing its history, process, impact in India, and opportunities highlighted by Indian government initiatives.

History of Anaerobic Digestion

The roots of anaerobic digestion trace back to ancient civilizations in China and India, where rudimentary systems captured biogas for cooking and lighting. The first modern digester was built in Bombay (now Mumbai), India in 1859. Since then, the technology has steadily evolved, particularly within rural India, to serve both energy and waste management needs.

Industrialization and Policy Support in India

– GOBARdhan Scheme: Referral site

– SATAT (Sustainable Alternative Towards Affordable Transportation): Referral site

– National Bioenergy Programme: Referral site

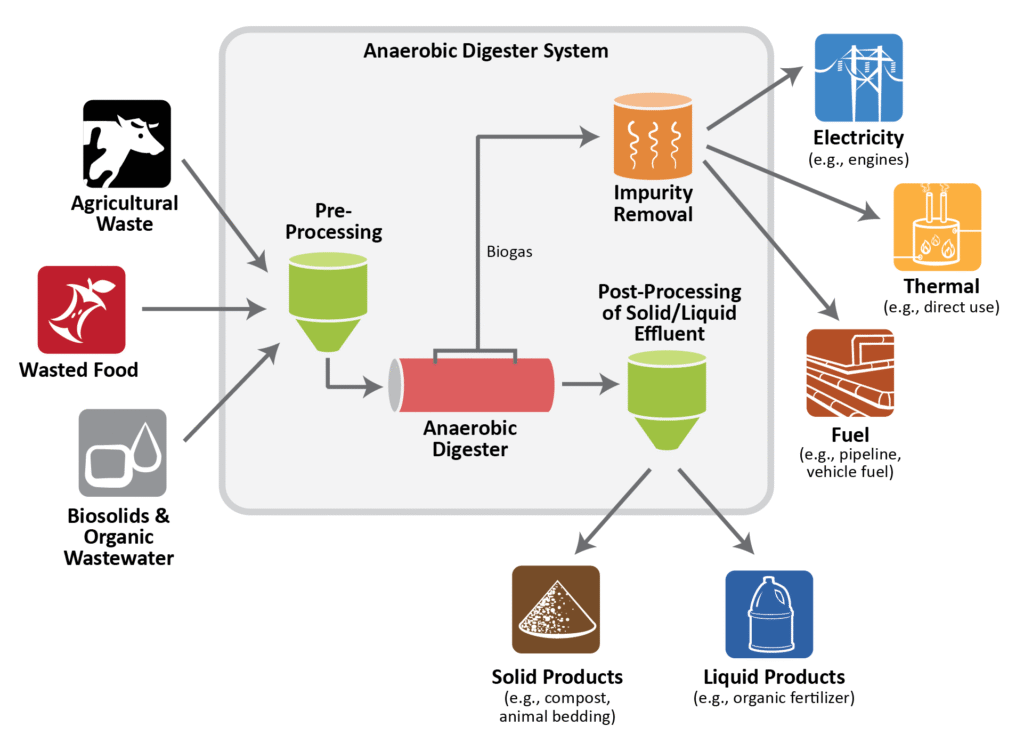

How the Process Works

Anaerobic digestion is a multi-stage biological process in which microorganisms break down organic material in the absence of oxygen. The process is typically represented in four distinct phases:

1. Hydrolysis

Complex organic matter like carbohydrates, fats, and proteins are broken down into simpler soluble compounds such as sugars, amino acids, and fatty acids.

2. Acidogenesis

The resulting compounds are further broken down by acidogenic (fermentative) bacteria into volatile fatty acids, alcohols, hydrogen, and carbon dioxide.

3. Acetogenesis

These intermediate products are then converted into acetic acid, more carbon dioxide, and hydrogen by acetogenic bacteria.

4. Methanogenesis

Finally, methanogenic archaea—a distinct group of anaerobic microorganisms—convert the acetic acid and hydrogen into methane (CH₄) and carbon dioxide (CO₂), resulting in biogas.

Outputs:

– Biogas: Mainly methane and carbon dioxide, used for energy.

– Digestate: Nutrient-rich residue used as organic fertilizer.

Impact of Anaerobic Digestion in India

Waste Diversion: Referral site

Cleaner Transportation Fuel (SATAT): Referral site

Case Study – Maharashtra (Deonar Biogas Plant): Referral site

Case Study – Mysuru: Referral site

Challenges and Opportunities

Challenges:

– High installation and operational costs.

– Need for trained manpower and regular maintenance.

– Policy implementation and regulatory clearances can be complex.

Opportunities:

– Financial support via GOBARdhan and MNRE.

– CBG’s growing commercial market under SATAT.

– Enhanced agricultural productivity through digestate use.

– Integration with smart waste management in smart cities.

– Potential for carbon credit generation under international sustainability programs.

– Job creation in rural areas for plant operations and maintenance.

– Decentralized energy independence for villages and institutions.

– Scope for academic and industrial R&D in microbial optimization and automation.

Conclusion

India’s anaerobic digestion journey is a powerful story of transformation. Once a basic rural technology, it now stands as a beacon of India’s clean energy ambitions. Government-backed initiatives are enabling AD to contribute meaningfully to waste management, energy security, and climate goals.

Call to Action

Ready to be part of India’s green energy movement?

✅ Access expert guidance on government schemes and compliance

✅ Get support with project planning, setup, and execution

✅ Discover how AD systems can generate revenue, reduce waste, and improve sustainability

Reach out today to schedule a free consultation with our anaerobic digestion experts.

Let’s work together to transform waste into energy and drive India’s clean energy revolution.