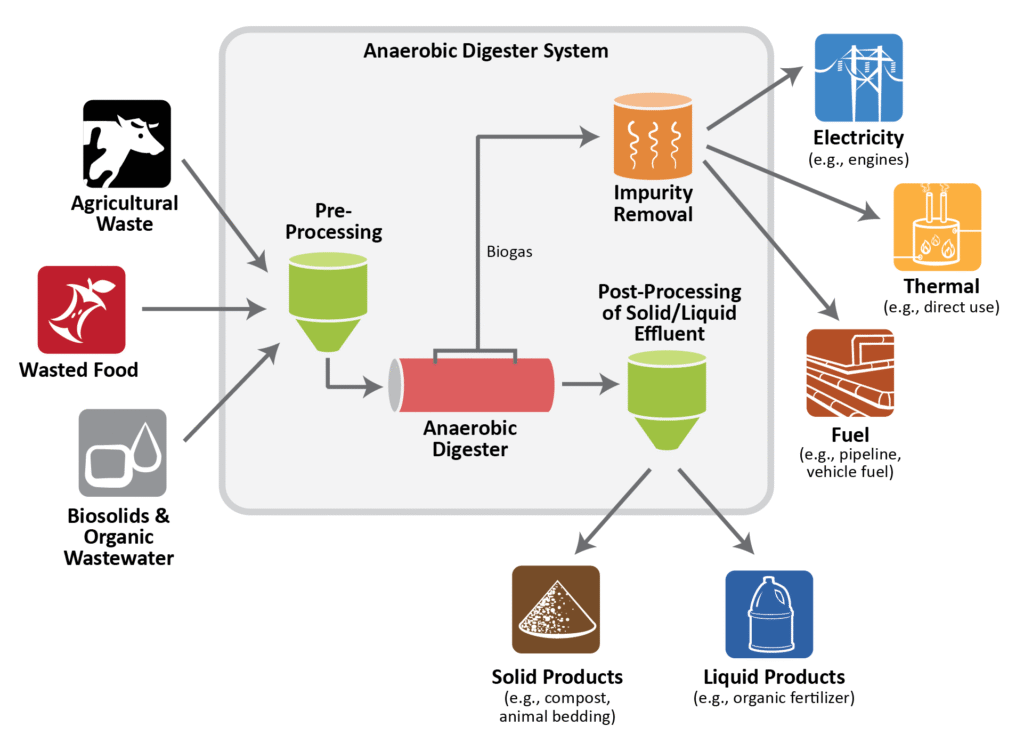

As the world embraces cleaner and more sustainable energy solutions, anaerobic digestion has emerged as a powerful technology to convert organic waste into biogas and nutrient-rich bio-fertilizer. At the heart of this process lies the digester — the controlled environment where microbes break down organic material in the absence of oxygen.

But did you know there are several types of digesters, each designed for specific conditions and feedstocks? Whether you’re a farmer, industrial operator, or sustainability enthusiast, understanding these digester types can help you make better decisions for your renewable energy goals.

🔍 What Is a Digester?

A digester is a sealed, oxygen-free container where organic materials like agricultural waste, food scraps, or wastewater sludge are broken down by bacteria. The process produces:

• Biogas (mainly methane and carbon dioxide), which can be used for electricity, heating, or fuel

• Digestate, a nutrient-rich residue that can be used as organic fertilizer

🔧 Types of Digesters

Here are the most commonly used digester types:

1. Batch Digesters

• How It Works: Loaded with material at once, sealed, and left to digest until the process is complete.

• Best For: Small-scale operations or seasonal waste.

• Pros: Simple design, low maintenance.

• Cons: Downtime between batches reduces continuous energy production.

2. Continuous Digesters

• How It Works: Fed regularly with new material; digested material flows out at the same rate.

• Best For: Commercial plants or farms with constant organic waste.

• Pros: Steady biogas production, higher efficiency.

• Cons: Requires more precise control and monitoring.

3. Plug Flow Digesters

• How It Works: Feedstock moves through the digester in a straight line (plug), without mixing.

• Best For: Thick, high-solid wastes like cow manure.

• Pros: Compact, efficient for certain waste types.

• Cons: Not ideal for very liquid or dilute waste.

4. Complete Mix Digesters

• How It Works: The contents are continuously stirred to maintain even digestion.

• Best For: A mix of solid and liquid waste.

• Pros: Flexible, handles a wide range of feedstocks.

• Cons: Higher energy and maintenance costs due to mixing.

5. Covered Lagoon Digesters

• How It Works: Large ponds covered with flexible membranes that capture biogas.

• Best For: Warm climates and dilute waste (e.g., dairy farms).

• Pros: Low cost, scalable.

• Cons: Less efficient in cold climates, large land area required.

💡 How to Choose the Right Digester?

When selecting a digester type, consider the following:

• Type and consistency of feedstock

• Daily waste volume

• Available land and budget

• Climate conditions

• Desired energy output and use

Consulting with an experienced bioenergy engineer or EPC provider can help you make the best investment.

🌍 Toward a Greener Future

Anaerobic digesters not only reduce greenhouse gas emissions but also turn waste into wealth. From rural communities to large-scale industrial plants, the right digester can unlock the full potential of biogas as a renewable energy source.

By understanding digester types and their applications, you’re one step closer to embracing a cleaner, circular economy.

Interested in deploying a digester system or upgrading an existing one?

📩 Contact us to learn more about custom-designed bioenergy solutions.